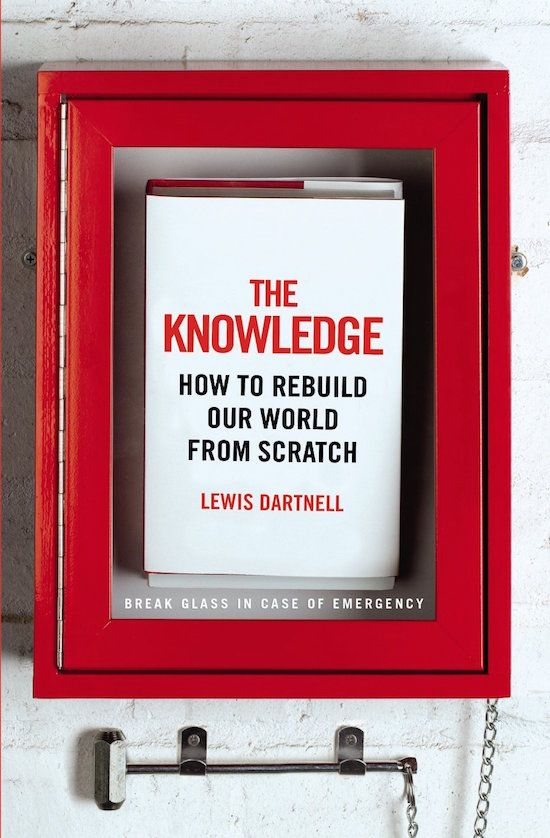

The Knowledge: How to Rebuild Our World from Scratch

"The Knowledge: How to Rebuild Our World From Scratch" is a fascinating thought experiment about how to build the ideal manual for a reboot of civilization. Dartnell decides that a good post-apocalypse reboot manual has a few critical ingredients:

- instructions for short-term survival

- a roadmap for longer-term rebooting of key agricultural, chemical, material, and energy industries,

- technological “shortcuts” that our ancestors didn’t discover for centuries (e.g. wheelbarrows, buttons, and using radios to avoid having to build longitude clocks), and

- a hearty regard for the scientific method.

Dartnell does a good job of sketching out the various technologies he mentions and includes fascinating historical tidbits about the technological trajectory that our civilization took. This book is almost more of a history of science book than an apocalypse-prepper book. Would I count on this being my primary post-apocalypse resource? No way. But in any case, it’s a fun read!

My favorite highlights below:

INTRODUCTION

This point is made very eloquently in Leonard E. Read’s 1958 essay written from the perspective of one of our most basic tools, “I, Pencil.” The astounding conclusion is that because the sourcing of raw materials and the methods of production are so dispersed, there is not a single person on the face of the Earth who knows how to make even this simplest of implements.

Denis Diderot explicitly regarded his Encyclopédie, published between 1751 and 1772, as a safe repository of human knowledge, preserving it for posterity in case of a cataclysm that snuffs our civilization as the ancient cultures of the Egyptians, Greeks, and Romans had all been lost, leaving behind only random surviving fragments of their writing. In this way, the encyclopedia becomes a time capsule of accumulated knowledge, all of it arranged logically and cross-referenced, protected against the erosion of time in case of a widespread catastrophe.

The solution can be found in a remark made by physicist Richard Feynman. In hypothesizing about the potential destruction of all scientific knowledge and what might be done about it, he allowed himself a single statement, to be transmitted securely to whichever intelligent creatures emerged after the cataclysm: What sentence holds the most information in the fewest words? “I believe,” said Feynman, “it is the atomic hypothesis . . . that all things are made of atoms—little particles that move around in perpetual motion, attracting each other when they are a little distance apart, but repelling upon being squeezed into one another.”

Likewise, many inventions seem obvious in retrospect, but sometimes the time of emergence of a key advance or invention doesn’t appear to have followed any particular scientific discovery or enabling technology. For the prospects of a rebooting civilization, these cases are encouraging because they mean the quick-start guide need only briefly describe a few central design features for the survivors to figure out exactly how to re-create some key technologies. The wheelbarrow, for instance, could have occurred centuries before it actually did—if only someone had thought of it. This may seem like a trivial example, combining the operating principles of the wheel and the lever, but it represents an enormous labor saver, and it didn’t appear in Europe until millennia after the wheel (the first depiction of a wheelbarrow appears in an English manuscript written about 1250 AD).

Without access to such readily available energy, how could a civilization following ours haul itself through a second industrial revolution? The solution, as we’ll see, will lie in an early adoption of renewable energy sources and careful recycling of assets—sustainable development will likely be forced on the next civilization out of sheer necessity: a green reboot.

A reboot manual would work best on two levels. First, you need a certain amount of practical knowledge handed to you on a plate, so as to recover a base level of capability and a comfortable lifestyle as quickly as possible, and to halt further degeneration. But you also need to nurture the recovery of scientific investigation and provide the most worthwhile kernels of knowledge to begin exploring.

CHAPTER 1 - THE END OF THE WORLD AS WE KNOW IT

During a severe crisis the social contract can snap altogether, precipitating a complete disintegration of law and order.

A common mantra of people who actively prepare for the apocalypse (called Preppers) is: “It is better to have a gun and not need it than to need a gun and not have it.”

Ironically, the safest place for a group to barricade themselves in and hunker down during the turbulence would be one of the fortresses dotted across the country, but now turned inside out in its purpose. Prisons are largely self-contained compounds with high walls, sturdy gates, barbed wire, and watchtowers, originally intended to prevent the inhabitants from escaping, but equally effective as a defensive refuge for keeping others out.

Thus a post-apocalyptic group of a few hundred men and women, all in the same place, ought to encapsulate sufficient genetic variability to repopulate the world.

For the best possible restart, you’d also want the survivors to number enough that a broad swath of skill sets is represented and sufficient collective knowledge is retained to prevent sliding backward too far. Thus an initial surviving population of around 10,000 in any one area (which for a large state such as Texas represents a survival fraction of only 0.04 percent), who are able to gather into a new community and work peacefully together, represents the ideal starting point for this thought experiment.

Fire will wreak devastation across great areas of the deserted cities, but it is water that will eventually bring certain destruction for all our carefully constructed buildings. The first winter after the Fall will see a spate of burst frozen water pipes, which will disgorge inside buildings during the following thaw. Rain will blow in through missing or broken windows, trickle down among dislodged roofing tiles, and overflow from blocked gutters and drains. Peeled paint from window and door frames will allow moisture to soak in, rotting wood and corroding metal until the whole insert falls out of the wall. The wooden structures—floorboards, joists, and roof supports—will also soak up moisture and rot, while the bolts, screws, and nails holding the components together rust.

The majority of our houses or apartment blocks will last, at most, a hundred years.

The steel-reinforced concrete of many modern buildings is a marvelous building material, but although more resistant than wood, it is by no means impervious to decay. The ultimate cause of its deterioration is ironically the source of its great mechanical strength. The steel rebars are cocooned from the elements by the concrete surrounding them, but as mildly acidic rainwater soaks through, and humic acids released by rotting vegetation seep into the concrete foundations, the embedded steel begins to rust inside the structures. The final blow for this modern construction technique is the fact that steel expands as it rusts, rupturing the concrete from the inside, leaving even more surface exposed to moisture and so accelerating the endgame. These rebars are the weak point of modern construction—and unreinforced concrete will prove more durable in the long run: the dome of the Pantheon in Rome is still going strong after two thousand years.

CHAPTER 2 - THE GRACE PERIOD

The dress code for the end of the world will be pragmatic: loose, durable trousers, layers of warm tops, and a decent waterproof jacket will keep you comfortable while you spend a lot more time in the open or in unheated buildings. Sturdy hiking boots may not look very glamorous, but in a post-apocalyptic world you really don’t want to lose your footing and break your ankle. Over the first few years, the best place to forage for clothing that has not yet been destroyed by insects or the penetrating damp would be large shopping centers.

In the immediate aftermath of the collapse, you won’t need wilderness survival skills such as rubbing sticks together to ignite tinder. There will be plentiful boxes of matches left in convenience stores and homes, and disposable lighters will continue working for years.

If you can't find matches or a lighter, there are less conventional methods for starting a fire using scavenged materials. If it’s a bright day, sunlight can be concentrated into a hot focus using a magnifying glass, a pair of eyeglasses, or even the curved base of a soda can that has been polished with a square of chocolate or a dab of toothpaste. Sparks can be generated by touching together jumper cables attached to an abandoned car battery and steel wool scavenged from a kitchen cupboard will ignite spontaneously when it is rubbed against the terminals of a 9-volt battery liberated from a smoke detector. There will be an abundance of excellent tinder lying around deserted human habitations, such as cotton, wool, rags, or paper, especially if you douse it in a makeshift fire accelerant like Vaseline, hair spray, paint thinner, or simply a drop of gasoline. And you won’t struggle to find fuel to burn, even in an urban environment. Populated areas are packed with combustible materials, from furniture and wooden fittings to garden shrubs, that can be thrown on a fire for heat and cooking.

After shelter and protection from the elements, the second priority on your list is to secure clean drinking water. Before the municipal water supply runs dry you should fill your bathtub and sinks to the brim with water, as well as any clean buckets or even strong polyethylene trash bags. These emergency water stores should be covered to keep them free from detritus and to block the light that allows algal growth. Bottled water can be scavenged from supermarkets and from water coolers in office buildings. Other reservoirs of water you’ll be able to drain include hotel and gym swimming pools, as well as the hot water tanks in any large building. In time, you’ll come to rely on water sources you’d normally have wrinkled your nose at. Every survivor will need at least three liters of clean water every day, and more in hot climates or with exertion. And keep in mind that this is for rehydration alone, and does not include water necessary for cooking and washing.

A more practical, longer-term solution for purifying larger volumes of water, once you have settled down after the Event, relies on a combination of filtration and disinfection. A rudimentary but perfectly adequate system for filtering out particles in murky lake or river water uses a tall receptacle such as a plastic bucket, a steel drum, or even a well-cleaned trash can. Punch some small holes in the bottom, and cover with a layer of charcoal, either taken from a hardware store or created yourself using the instructions here. Alternate layers of fine sand and gravel on top of the charcoal. Pour the water into your receptacle, and as it drains through, it will be effectively filtered of most particulate matter. The first option for disinfecting this filtered water to eliminate waterborne pathogens is to use dedicated water-purification treatments, such as iodine tablets or crystals available from camping stores. If you can’t find any, there are some surprising alternatives that will also work perfectly well, such as chlorine-based bleaches formulated for household cleaning. Just a few drops of a 5 percent liquid bleach solution that has sodium hypochlorite listed as the main active ingredient will disinfect a whole liter of water in an hour. But carefully check the label to ensure that the product doesn’t also contain additives such as perfumes or colorants that may be poisonous. Several fluid ounces of bleach found under a kitchen sink can purify around 500 gallons of water—almost two years’ supply for one person.

Plastic bottles can be used not just for storing water, but for sterilizing it as well. Solar water disinfection, or SODIS, employs only sunlight and transparent bottles, and is recommended by the World Health Organization for decentralized water treatment in developing nations—a perfect low-tech option for the post-apocalyptic world. Tear the labels off clear plastic bottles—but don’t use bottles bigger than two liters, as the crucial part of the Sun’s rays won’t be able to penetrate all the way through—fill them with the water to be disinfected, and lay them down outside in full sunlight. The ultraviolet component of the Sun’s rays is very damaging to microorganisms, and if the water warms up to above 50 degrees Centigrade (122°F), this deactivating effect is greatly enhanced. A good system is leaning a sheet of corrugated iron angled to the Sun and stacking the water bottles in the grooves. Painting the sheet black helps the heat sterilization effect.

By far the largest reserve of preserved sustenance, however, will be the rows upon rows of canned food that fill the supermarket shelves.

A single average-size supermarket should be able to sustain you for around 55 years — 63 if you eat the canned cat and dog food as well.

Each gas station holds a subterranean lake of fuel of typically around 30,000 gallons, enough for an average family car to drive more than a million miles along post-apocalyptic roads.

the modern GPS navigation devices we have become so reliant upon will malfunction surprisingly quickly after satellites lose the regular uplink from their command center. Positional accuracy will drop to about half a kilometer within two weeks of the Fall and around 10 kilometers within six months, and the system will be utterly useless within just a few years as the satellites drift out of their precisely coordinated orbits.

Antibiotics marketed for farm and pet animals, and even for fish aquariums, are exactly the same as for humans and should not be overlooked in your scavenging.

One of the earliest uses of cyanoacrylate adhesive, better known as superglue, was for rapidly closing wounds of US soldiers during the Vietnam War. This application would become very important again in preventing life-threatening infections in a post-apocalyptic world if you don’t have immediate access to sterilized suturing needles and threads.

In the immediate aftermath, the major problem with built-up areas will be the huge numbers of bodies of those who died in the catastrophe. With no organized service to remove and dispose of corpses in a sanitary way, not only will the stench of decay be unbearable for the first months, but the rot and decomposition will pose a severe health hazard. As with any disaster, transmissible diseases from contaminated water supplies will be a big concern.

Mechanically minded survivors shouldn’t have too much trouble cobbling together rudimentary windmills from salvaged materials. Thin steel sheets could be cut and curved into the radial vanes of a large fan, mounted on the hub of a wheel, and the torque could be transferred by a chain and bicycle gear set. The principal step is to convert that rotational energy into electricity, and for that you’ll want to salvage a suitable ready-made generator. A source of particularly handy and compact versions is so ubiquitous in the modern world that you would be forgiven for overlooking them. There are around a billion motor vehicles on the planet now—with the US having the most of any nation, around a quarter of the total—and each of them has a salvageable alternator. The car alternator is an ingenious mechanism. Spin the shaft and a perfectly steady 12 volts of direct current appears across its terminals, regardless of how quickly the shaft is turned, making it perfectly suited to be repurposed for post-apocalyptic small-scale power generation.

Car batteries are very reliable, but are designed to give a high-current, brief burst of power to spin the starter motor. They’re poorly suited to providing the sustained, steady supply of electrical energy that you would need for powering your new off-grid life; in fact, they are easily damaged if persistently allowed to discharge by more than about 5 percent. An alternative design of rechargeable lead-acid battery, known as a deep cycle, discharges at a much slower rate and can have almost its entire capacity repeatedly drained and recharged without problems. It’s this kind of battery that you want to forage for in the immediate aftermath. Try caravans and other RVs, motorized wheelchairs, electric forklift trucks, and golf carts—hence the recommended trip to the course.

The easiest thermoplastic to recycle with rudimentary methods is polyethylene terephthalate (PET). The simple way to tell which specific polymer your scavenged plastic items are made from is to check the recycling identification code imprinted on them. PET is distinguished with (1)—plastic drinking bottles, for example, are almost exclusively PET—and you may also have some success recycling (2), high-density polyethylene (HDPE), and (3), polyvinyl chloride (PVC). However, while glass can be melted and re-formed indefinitely, the quality of plastic products degrades with exposure to sunlight and the oxygen in the air, and they become weaker and more brittle each time they are recycled. So while a post-apocalyptic society would be able to feed on our carcass of metal and glass, the age of plastics will inevitably draw to an end, until sufficient chemical proficiency can be relearned.

One of the first things you’ll want to find are old-fashioned walkie-talkies for keeping in contact with other members of your group when you’re separated while out scavenging. For long-range communication, citizens band or ham radio sets will become pretty valuable for trying to establish contact with other pockets of survivors.

CHAPTER 3 - AGRICULTURE

Every modern strain of crop represents thousands of years of diligent selective breeding, and if you lose ready-domesticated species, you may lose any hope of shortcutting the rebuilding of civilization.

Modern industrialized agriculture is astonishingly successful, with an acre today producing two to four times more food than the same land provided a hundred years ago. But the only way that farms today can function, growing dense monocultures on the same land and still producing high yields year after year, is by spraying potent herbicides and pesticides to maintain an iron-fist control over the ecosystem, and by the liberal application of chemical fertilizers.

All of these herbicides, pesticides, and artificial fertilizers are synthesized using fossil fuels, which also power the farmyard machinery. In a sense, then, modern farming is a process that transforms oil into food — with some input from sunshine—and consumes around ten calories of fossil fuel energy for every calorie of food actually eaten. With a collapse of civilization and the disappearance of an advanced chemical industry, you’ll need to relearn traditional methods. Today, organic produce is the preserve of the wealthy; in the aftermath it will be your only option.

It’s easy to get a visual check on soil composition. Fill a glass jar one-third of the way with soil (picking out any hard clumps, stems, or leaves) and top it off almost to the brim with water. Screw on a lid, and shake vigorously until all lumps have been broken up and you have a uniform muddy soup. Let the jar stand undisturbed for a day or so, allowing time for the suspension to settle back down and the water to be nearly clear again. The different grains will have sedimented out in order of their particle size to show distinct layers or bands. The bottom band is the coarse-grained sand component of the soil, the middle layer is silt, and the very top layer holds the finest clay particles, allowing you to visually judge their proportions in the mixed soil.

Corn, rice, and wheat, as well as barley, sorghum, millet, oats, and rye, are all cereal crops: varieties of grass. This dominance of cereals in our diets, coupled with the fact that much of the meat we consume comes from livestock fed by either grazing in pastures or on grain fodder, means that much of humanity subsists, either directly or indirectly, by eating grass. And it is on this hugely significant category of crops that survivors will need to survive.

The combine harvester is undoubtedly one of the most important inventions of recent history, freeing so many of us from being required to work in the fields and enabling us to perform other roles in a complex society.

In the immediate post-apocalyptic world, the husbandry of plants and of animals will once again become inseparable, mutually supporting endeavors.

The Norfolk four-course rotation is the most successful of these historical systems and became widespread only in the eighteenth century, spearheading the British agricultural revolution. In the Norfolk system, succession of crops through each plot follows the order: legumes, wheat, root crops, barley.

Reverting to small-scale methods, five acres of land will be enough to support a group of up to ten people: wheat for bread, barley for beer, a diverse range of fruits and veggies, as well as cattle, pigs, sheep, and chickens for meat, milk, eggs, and other products.

But with a little more ingenuity, some of the human and farmyard waste can be turned into something altogether more useful with a bioreactor. In a compost heap the objective is to keep everything well aerated so that oxygen-needing bacteria and fungi can readily decompose the matter. But if instead you hold the waste in a closed vessel, blocking oxygen from getting in, anaerobic bacteria thrive and partly convert the organic material into flammable methane gas. This can be piped into a simple gas storage facility constructed from a concrete-lined pool filled with water with an upturned metal container fitted snugly within it. As the methane bubbles up into the storage tank, the water forms an air seal, and the metal gas collector rises. The weight of the floating storage tank provides gas pressure, and the methane can be piped off to supply stoves, gas for lighting, or even, as we’ll see later, fuel for vehicle engines. A metric ton of organic waste can produce at least 50 cubic meters of flammable gas, equivalent to the energy of a full tank of gasoline. (It is not surprising that such biogas digesters became common across fuel-starved Nazi-occupied Europe during the Second World War.) The microbial growth slows considerably at lower temperatures, so it’s important to keep the bioreactor insulated, or even siphon off some of the methane produced to heat it.

CHAPTER 4 - FOOD AND CLOTHING

Cooking is only one kind of processing that we apply to food before consumption. The capability to keep food safely for protracted periods beyond its immediate collection is a fundamental prerequisite for the support of civilization.

The easiest method of preserving food is simply to desiccate it. Without much available water, microbes struggle to grow (this is why it’s also critical to dry your harvested grain before storing it in silos). The traditional technique is air- or sun-drying, suitable for fruit such as tomatoes as well as meat to make biltong or beef jerky, but it is a slow process and not suitable for large bulks of food.

Bread is essentially no more than a cooked gruel, but as an effective pathway for nourishment it has underpinned civilization since its very birth. The basic recipe is ludicrously simple: grind some grass seeds into a powdery flour, mix with water into a pasty dough, then roll out and cook slowly, perhaps even just on a hot stone by the fire. This makes an unleavened flatbread, which is still exceedingly common today as chapati, naan, tortilla, khubz, and pita bread.

The guide given here is for isolating the correct microbes for baking a sourdough, the first leavened bread to be baked, around 3,500 years ago in ancient Egypt, and still popular today among craft bakers. Make up a mixture of one cup of flour (whole-grain is best for this initial process) and half to two-thirds of a cup of water; cover and allow it to sit in a warm place. Check after twelve hours for signs of growth and fermentation, such as bubbles forming. If none are apparent, stir and wait another half day. Once you get fermentation, throw half of the culture away and replace with fresh flour and water in the same proportions, repeating this refill twice a day. This gives the culture more nutrients to reproduce and continually doubles the size of the microbial territory to expand into. After about a week, once you have a healthy-smelling culture reliably growing and frothing after every replenishment, like a microbial pet thriving on the feed left in its bowl, you are ready to extract some of the dough and bake bread.

One exceedingly useful item to scavenge from the supermarket shortly after the Fall would be a bottle of craft ale that contains a sediment of live yeast at the bottom, so as to save this handy bug for posterity.

Encouragingly for an accelerated reboot, there was no missing prerequisite technology that prevented the development of canned food centuries earlier in our history — perhaps even skilled Roman glassworkers could have made reliably sealable airtight vessels — so survivors can start canning food soon after the Fall.

Whether your garments are stitched from leather or woven fabric, the next problem is how to attach them securely to your body. Disregarding zippers and velcro as too complex to be fabricated by a rebooting civilization, you’re low on options for easily reversible fastenings. The best low-tech solution never occurred to any of the ancient or classical civilizations, yet is now so ubiquitous it has become seemingly invisible. Astoundingly, the humble button didn’t become common in Europe until the mid-1300s. Indeed, it never was developed by Eastern cultures, and the Japanese were absolutely delighted when they first saw buttons sported by Portuguese traders.

CHAPTER 5 - SUBSTANCES

The traditional method for this anaerobic transformation of wood—the specialist craft of the collier—was to build a pyre of logs with a central open shaft, and then smother the whole mound with clay or turf. The stack is ignited through a hole in the top, and then the smoldering heap is carefully monitored and tended over several days. You can achieve similar results more easily by digging a large trench and filling it with wood, starting a hearty blaze, and then covering over the trench with scavenged sheets of corrugated iron and heaping on soil to cut off the oxygen. Leave it to smolder out and cool. Charcoal will prove indispensable as a clean-burning fuel for rebooting critical industries such as the production of pottery, bricks, glass, and metal, which we’ll come to in the next chapter.

Modern candles are composed of wax derived from crude oil, and the availability of beeswax will always be limited, but you can make a perfectly functional candle from rendered animal fat. Boil meat trimmings in salty water, and scoop the hardening layer of floating fat off the surface. Pig lard produces a smelly, smoky candle, but beef tallow or sheep fat are passable. Pour molten tallow into a mold, or even just dip a row of dangling wicks into hot tallow to coat them; allow them to cool and set in the air. Then repeat, building up layer after layer until you have substantial candles.

It is the chemical transformations that limestone undergoes when you heat it, however, that are particularly useful for a great range of civilization’s needs. If calcium carbonate is roasted in a sufficiently hot oven — a kiln burning at least at 900°C — the mineral decomposes to calcium oxide, liberating carbon dioxide gas. Calcium oxide is commonly known as burned lime, or quicklime. Quicklime is an extremely caustic substance, and is used in mass graves—which may well be necessary after the apocalypse—to help prevent the spread of diseases and to control odor. Another versatile substance is created by carefully reacting this burned lime with water. The name quicklime comes from the Old English, meaning “animated” or “lively,” as burned lime can react so vigorously with water, releasing boiling heat, that it seems to be alive. Chemically speaking, the extremely caustic calcium oxide is tearing the molecules of water in half to make calcium hydroxide, also called hydrated lime or slaked lime.

If you’re really pulling yourself up by your bootstraps, you can roast limestone in the center of a large wood fire in a pit, crush and slake the small batches of lime produced, and use them to make a mortar suitable for building a more effective brick-lined kiln for producing lime more efficiently.

Soap lifts greasy stains from your clothes and washes the bacteria-laden oil off your skin because it is able to mingle comfortably with both fatty compounds and water, which do not themselves mix.

The pressing question, therefore, is where to get alkali in a post-apocalyptic world without reagent suppliers. The good news is that survivors can revert to ancient chemical extraction techniques and the most unlikely-seeming source: ash.

The white crystals left behind are actually a mixture of compounds, but the main one from wood ash is potassium carbonate. If you burn a heap of dried seaweed instead and perform the same extraction process, you can collect soda ash, or sodium carbonate. Along the western shoreline of Scotland and Ireland the gathering and burning of seaweed was a major local industry for centuries. Seaweed also yields iodine, a deep-purplish element that you’ll find very useful as a wound disinfectant as well as in the chemistry of photography, which we’ll come back to.

Both potash and soda ash are alkalis; indeed, the very term derives from the Arabic al-qalīy, meaning “the burned ashes.”

If you now mix your extract into a boiling vat of oil or fat, you can saponify it, creating your own cleansing soap. You can therefore keep the post-apocalyptic world clean and resistant to pestilence with just base substances like lard and ash, and a little chemical know-how. This hydrolysis reaction is enhanced, however, if you use a more strongly alkaline solution: lye. This is where we return to slaked lime, calcium hydroxide.

the crucial alkali ammonia can also be produced by distinctly low-tech means: fermenting pots of piss.

Saponification of fat molecules will also give you another useful byproduct. The chemical component of the lipid that acts as the linker block grasping the three fatty acid tails, glycerol, is left behind after lard is transformed into soap. Glycerol is itself fabulously handy, and can be easily extracted out of a lathery soap solution. The fatty acid salts of the soap itself are less soluble in brine than in fresh water, and so adding salt will cause them to sediment out as solid particles, leaving behind the glycerol in the fluid. Glycerol is a key raw material for making plastics — and explosives (which we’ll come to in Chapter 11).

Wood can offer so much more than just carbon fuel and alkali from its ashes. In fact, wood was once the major source of organic compounds—providing chemical feedstocks and precursor substances for a vast array of different processes and activities—and was superseded only in the late nineteenth century by coal tar and the subsequent development of petrochemicals from crude oil. In a post-apocalyptic world, therefore, where you may well find yourself without accessible coal or a continuing supply of oil, these older techniques will support the rebooting of a chemical industry.

By the second half of the seventeenth century, chemists had noticed that burning wood in a closed container released flammable gas and also vapors that could be condensed back into a watery fluid. These products came to be known as pyroligneous (a Greek-Latin hybrid word for fire and wood) and are a complex mixture of many different compounds. An ideal stepping-stone for a recovering society to leapfrog to would be to bake wood in a sealed metal compartment, with a side pipe drawing off the released fumes and coiling through a bucket of cold water to cool and condense the vapors. The released gases do not condense, and so can be used to fuel the burners beneath the wood-baking compartment. We’ll see in Chapter 9 how these pyroligneous gases can even be used to fuel a vehicle.

Acetone is a good solvent and is used as the base for paints—it is the distinctive scent of nail polish—and as a degreaser. It is also important in plastics production and is used in the making of cordite, the explosive propellant used for bullets and shells during the First World War. In fact, there was a point when Britain feared losing the war due to an acute shortage of acetone. The huge demand for cordite far exceeded what could be produced by the dry distillation of wood, even with imports of the solvent from timber-rich countries like the United States. Production was maintained by the invention of a new technique, using a particular bacterium to secrete acetone during fermentation, and huge amounts of horse chestnuts collected by schoolchildren as the feed.

The timber of any tree will provide differing quantities of these crucial chemicals by dry distillation, but resinous hardwoods, including conifers such as pines, spruces, and firs, yield more pitch. Birch bark is a particularly good source of pitch that has been used since the Stone Age to stick fletching feathers to arrows.

Distillation is such a universally useful technique for separating a blend of fluids, exploiting the principle that different liquids boil at specific temperatures, that a recovering society would do well to master it as early as possible. Distillation fractionates, or separates, the various products of heat-decomposed wood and extracts concentrated alcohol from a fermented slop, as we’ve already seen; it also teases apart crude oil into a diverse selection of different constituents, from thick viscous asphalt to light volatile components like gasoline. And once a certain level of industrial capability is achieved, even air itself can be distilled. The gas mixture is chilled to around -200°C by using a repeated expansion and cooling process and is held in a vacuum-insulated capsule, like a giant thermos flask for taking coffee on a hike. The liquid air is then allowed to warm, and as each separate gas boils off it is collected, the pure oxygen used, for example, for hospital breathing masks.

The trick is to employ a chemical pathway that was never used industrially in our development. Sulfur dioxide gas can be baked out of common pyrite rocks (iron pyrite is notorious as fool’s gold, and pyrites also form common ores of lead and tin) and reacted with chlorine gas, which you get from the electrolysis of brine, using activated carbon (a highly porous form of charcoal) as a catalyst. The resulting product is a liquid called sulfuryl chloride that can be concentrated by distillation. This compound decomposes in water to form sulfuric acid and hydrogen chloride gas, which should itself be collected and dissolved in more water for hydrochloric acid. Luckily, there is also a simple chemical test for whether a rock is a pyrite mineral (a metal sulfide compound): dribble a little dilute acid on the rock, and if it fizzes and gives off the stench of rotting eggs, you’ve got what you’re after (but hydrogen sulfide gas is poisonous, so don’t sniff too much!).

Today, more sulfuric acid is manufactured than any other compound—it is the linchpin of the modern chemical industry, and will also be crucial in accelerating a reboot. Sulfuric acid is so important because it’s good at performing several different chemical functions. Not only is it potently acidic, it is also strongly dehydrating and a powerful oxidizing agent. Most of the acid synthesized today is used to produce artificial fertilizers: it dissolves phosphate rocks (or bones) to liberate the crucial plant nutrient phosphorus. But its uses are virtually limitless: preparing iron gall ink, bleaching cotton and linen, making detergents, cleaning and preparing the surface of iron and steel for further fabrication, creating lubricants and synthetic fibers, and serving as battery acid.

CHAPTER 6 - MATERIALS

Brick, glass, concrete, and steel are the literal building blocks of our civilization. But they all come from the humblest of beginnings: mucky earth, soft limestone, sand, and rocky ore that we dig from the ground and transmute with fire into the most useful materials of history.

Slaked lime is able to transform from a spreadable paste back into a material set hard as stone. Mixed with a little sand and water, slaked lime forms mortar, which has been used to firmly stick bricks together into sturdy load-bearing walls for thousands of years. Mix it with less sand, and perhaps stir in some fibrous material like horsehair, and you have a plaster for spreading as a smooth finish on walls.

Lime mortars have been used for millennia, but it was a substance first mass-produced by the Romans that changed the nature of building. The Romans noticed that cementum made by mixing slaked lime with volcanic ash, known as pozzolana, or even pulverized brick or pottery, sets far more quickly than lime mortar and is several times stronger. And with the fabulously strong mineral glue that is cement, you can do far more than just stick together ordered rows of bricks. You can also bond jumbled aggregations of rocks or rubble—that is, you can make concrete. This revolution in construction technology allowed the Romans to build awe-inspiring structures such as the Collosseum and the vast bulging roof of the Pantheon in Rome, which is still the largest single-piece concrete dome in the world.

What you ideally want to be able to reattain as rapidly as possible after the Fall is the mastery not just of iron, but of its carbon alloy, steel. Steel contains a blend of iron and carbon atoms and is so much more than the sum of its parts. The inclusion of carbon changes the metal’s properties substantially, and by varying the proportion of carbon soaked into the alloy recipe, you can control the strength and hardness of the steel to suit different applications.

The reason that we’ve been able to exploit hard iron through the history of civilization is that it temporarily changes its physical properties when hot, softening to become malleable enough to be beaten into shape, rolled into sheets, or drawn into pipes and wires. This is a fundamental point, because it means you can use iron tools to work on iron to produce more tools.

The crucial knowledge for fully exploiting iron for tools is the principle of hardening steel—quenching and tempering. Steel is hardened by heating it red-hot so that the internal structure of iron-carbon crystals converts to a particularly rigid conformation (which is nonmagnetic, allowing a simple test during heating). If allowed to cool slowly afterward, though, this crystal reverts back to its previous form, and so you need to chill it rapidly to essentially freeze the desired structure: quenching the piece by dunking it, sizzling, into water or oil. However, a hard substance is also brittle—and a steel hammer, sword, or spring that shatters is useless—so after quenching a piece needs to be tempered. You do this by reheating to a lower temperature for a period of time so that a proportion of the crystal structure relaxes: you are deliberately trading off some of the strength to return a little flexibility to the material. Tempering allows you to tune the material properties of steel, a crucial ability for designing the appropriate metal for the intended task.

An even higher temperature of around 6,000°C is generated by an electric arc welder: brandishing the power of lightning. Rigging up a row of batteries, or a generator, will produce enough of a voltage that a constant spark, or arc, will leap between the target metal and a carbon electrode, to weld or cut as the electrode is drawn across the surface. Such jury-rigged oxyacetylene torches or arc cutters would be indispensable equipment for salvage crews sent into the dead cities to disassemble the ruins and scavenge the most valuable materials. One very effective way for melting down scrap steel for recycling is the electric arc furnace. It’s essentially a giant arc welder: large carbon electrodes surge electricity through the metal to melt it, with limestone flux used to remove impurities as slag on top and the molten steel being poured as if from a kettle. Running an arc furnace from renewable electricity would be an important technology to try to leapfrog to in order to relieve demands on fuels for thermal energy in the post-apocalyptic world.

An incredibly elegant example has been provided by a machinist in the 1980s who created a fully equipped metalworking shop—complete with lathe, metal shaper, drill press, and milling machine—starting with little more than clay, sand, charcoal, and some lumps of scrap metal. Aluminum is a good choice, as it has a low melting point for easy casting and is very corrosion-resistant, so it will be scavengeable even long after the apocalypse.

Astoundingly, not only is the lathe capable of duplicating all of its own components to create more lathes, but starting from absolute scratch, you can even produce, during the rudimentary stages of construction of your first lathe, the remaining components needed to complete it.

In our history it took a long process of reiterative refinement to make the first precise metal screw thread, from which many others can then be constructed, and you would want to avoid having to repeat this.

Whereas the lathe applies a tool to a rotating workpiece, the milling machine bears a rotating tool against the workpiece, and is exceedingly versatile — once you have a milling machine you can create pretty much anything else.

The key to modern civilization is efficiently making steel in bulk. Here’s how you do it. The solution is to force a powerful stream of air up the furnace stack to ferociously intensify combustion.

This high-carbon iron, with its lowered melting point, can be remelted and poured into a mold like hot wax. Cast iron is therefore greatly convenient for quickly fabricating items like cooking pots, pipes, and machinery parts, and the Victorians mass-produced cast-iron girders. But cast iron also has one great disadvantage: the high carbon content makes the metal brittle, and cast-iron bridges, for example, have the nasty habit of collapsing if their structural components are bent or stretched.

The Bessemer converter is a giant pear-shaped bucket, lined with refractory bricks and mounted on pivots so it can be tipped. The vessel is charged with molten pig iron, and then air is pumped in through holes in the bottom, not unlike the action of a bubbling aquarium aerator. The excess carbon reacts with the oxygen and escapes as carbon dioxide gas, and other impurities are also oxidized and scrubbed out into the slag. One lucky outcome is that as the carbon burns it releases enough heat to keep the iron molten throughout. The difficulty is that it is hard to judge the operation accurately enough to remove almost all of the carbon, but leave just under 1 percent. The trick for nailing the final composition, obvious in retrospect, is to run the conversion long enough that you are sure absolutely all of the carbon has been removed, and then simply mix exactly the final percentage you want back into the pure iron. This Bessemer process was the first method in history for cheaply mass-producing steel, and you’d want to leapfrog back to this point as quickly as you can.

Glass is sometimes produced naturally: if you dug around in the sand of a desert you might be lucky enough to unearth curious long hollow tubes of fused silica, often resembling the complex branched root system of a tree. A structure like this is called a “fulgurite,” or “thunderbolt stone,” and is created when lightning strikes dry sand. The electrical current surges underground and produces temperatures high enough to fuse silica grains together into a glassy tube.

So the vast majority of glass made today for windowpanes or bottles is soda-lime glass — a solution of soda and lime dissolved in sand that freezes at everyday temperatures.

As well as being transparent, heat-resistant, and strong enough to make thin-walled vessels, glass is also largely inert. And this has been critical for every aspect of chemistry research. Glass can be molded or blown into all the varied forms of laboratory apparatus: test tubes, flasks, beakers, burettes, pipettes, pipes, condensers, fractionating columns, gas syringes, measuring cylinders, and watch glasses. It’s hard to see how chemistry could ever have progressed without access to a material that is both inert and see-through, allowing us to watch what happens in a reaction without tainting it.

Of the six instruments crucial to the development of the modern scientific enterprise in the seventeenth century, all of which would be indispensible in rediscovering the world after an apocalypse—pendulum clock, thermometer, barometer, telescope, microscope, and vacuum chamber with air pump—all but one of them, the pendulum clock, rely utterly on the unique combination of properties offered by glass.

CHAPTER 7 - MEDICINE

Today, most of us in the West will eventually succumb to chronic diseases such as heart disease or cancer as the body starts malfunctioning with age; but, as throughout our history and in developing nations to this day, in a post-apocalyptic world it is infectious contagions that will return as the scourge of humanity.

On an individual level, the single most effective thing you can do to protect yourself from potentially life-threatening disease and parasites is to regularly wash your hands (using the soap we’ve learned to make in Chapter 5). This isn’t some ritualistic hangover from modern civilization, a matter of good manners to keep your mitts looking nice, but a basic survival skill—do-it-yourself health care. Alongside this, as a society you need to ensure that your drinking water isn’t contaminated with your own or anyone else’s excrement. These are the central tenets of modern public health, and retaining the most basic principles of germ theory will keep the post-apocalyptic society healthier than that of our ancestors even as late as the 1850s.

If you do succumb to an enteric infection, the good news is that the condition is often entirely survivable. Even something as historically devastating as cholera is not actually directly lethal: you die from rapid dehydration resulting from the profuse diarrhea, losing as much as 20 liters of body fluid a day. The treatment, therefore, is astoundingly straightforward, even though it was not widely adopted until the 1970s. Oral rehydration therapy (ORT) consists of no more than a liter of clean water with a tablespoon of salt and three tablespoons of sugar stirred in, to replace not only the water lost in the sickness, but also your body’s osmolytes. To survive cholera you don’t need advanced pharmaceuticals, just attentive nursing.

The tool that transformed medical diagnosis is astonishingly simple. The stethoscope need be no more than a hollow wooden tube held to the ear and pushed against the patient’s body, or even a rolled-up bundle of papers, which was how the tool was invented in 1816.

CHAPTER 8 - POWER TO THE PEOPLE

When you divide national energy consumption by total population, you find that each individual living in the United States actually uses nearly 90,000 kWh every year, while a European uses just over 40,000 kWh. Before the mechanical revolution in the Middle Ages that began the widespread use of waterwheels and windmills, and later, industrialization based on the exploitation of fossil fuels, the effort needed for agriculture, manufacture, and transportation was provided by muscle power alone. If we put this modern energy consumption into perspective, 90,000 kWh is equivalent to every American having a team of fourteen horses, or more than a hundred humans, working flat-out, 24/7 for them.

Luckily it doesn’t take much technical know-how to build a far more capable and powerful waterwheel. The overshot wheel became widely exploited across Europe during the supposedly ignorant and stagnant “Dark Ages” following the fall of the Roman Empire, and, despite similarities in overall appearance, functions on a completely different principle than the primitive undershot wheel. Rather than being stuck into the flow, the bottom of the overshot wheel is held clear of the tailrace, and water is delivered to the very top of the wheel by a chute. The overshot wheel derives its torque not from the impact of a current, but from the energy relinquished by the water as it falls. This design is far more efficient and can capture as much as three-quarters of the energy held in the head of water. Fit a sluice gate to the chute to control the flow onto the wheel, and if the stream is dammed to create a mill pond, a reservoir of energy can be built up until it is required to be expended (something that wasn’t attempted until the sixth century AD, half a millennium after the first vertical waterwheels were used, but could be leapfrogged to during a reboot).

Medieval Europe became the first civilization in human history to base its productivity not on human muscle power — the labors of coolies or slaves — but on the exploitation of natural power sources.

You might think that steam engines represent exactly the sort of transitional technological level that you would aspire to leapfrog over during a reboot, straight to internal combustion engines or steam turbines, which we’ll explore in detail later. But steam engines offer two major advantages over more advanced alternatives, and so you may need to recapitulate this developmental stage. First, they are external combustion engines and don’t require refined gasoline, diesel, or natural gas to run—they are much less fussy, and their boiler can be fired with pretty much anything that burns, including scrap wood or agricultural waste. Second, a simple steam engine can be constructed with much more rudimentary machine tools and materials and with far more forgiving engineering tolerances than a more complex mechanism.

The easiest rechargeable battery to build from scratch is the lead-acid battery, common today in cars. A sheet of lead is used for each electrode, and bathed in sulfuric acid electrolyte. Both electrodes will react with the acid to make lead sulfate, but during charging you will convert the positive one to lead oxide (lead rust) and the negative one to lead metal, which is neatly reversible again as the battery discharges. Each of these cells will produce just over 2 volts, and so six of them wired together in a series gives you the 12 volts of a car battery.

The problem with such designs is that the extensive system of gears needed to multiply up the slow turning wastes a lot of the energy. The solution for windmills is to fundamentally change the design. Instead of deploying broad sails that catch large amounts of the wind as it passes, but also generate lots of turbulence and drag and can therefore never spin very fast, modern wind turbines sport a triplet of long, slender blades. These are based on the lessons of aerodynamics learned from developing the propellers on aircraft, and although their much smaller surface area means they struggle to get going at slow wind speeds, they can spin incredibly rapidly in a stiffer breeze and convert far more of the rushing energy into electricity.

Despite the efficiency of wind or water turbines and their harnessing of renewable energy, most of our electricity today is not generated in this way. In fact, the age of steam never really ended. Though we don’t use steam engines as prime movers for machinery or vehicles anymore, more than four-fifths of the electricity used around the world is generated using steam: firing a boiler with the heat released by combusting coal or gas, or by the disintegration of unstable heavy atoms in a nuclear fission reactor.

The beauty of electricity is that you no longer have to build all of your industry on top of windy hills, near fast-flowing rivers, or within easy transport distance of forests or coalfields, as our ancestors had to before the nineteenth century. You only need to place your power generators in these sites, and then zip the electrical energy down wires to wherever it’s needed. This is something we’ve come to take for granted. Just a century ago, all the energy for a household would have to be physically delivered: oil for lamps, charcoal or coal for cooking and heating; Victorian houses needed an outside coal bunker the size of a small room to hold enough fuel to keep warm over the winter. Today, electricity is piped directly throughout the home, supplying energy right to where it’s needed—cleanly, silently, and without requiring any storage.

Combined heat and power (CHP) plants address the absurdity of power stations simply discarding vast amounts of heat though their cooling towers, when all the buildings in surrounding towns burn yet more fuel to heat themselves. Sweden and Denmark are leading the world in their use of CHP, first driving turbines to generate electricity but then using the hot steam for other purposes, such as heating buildings in the local area. They are fired by burning natural gas as well as biofuels like wood waste, timber from sustainable forests, or agricultural waste, and can approach 90 percent efficiency for electricity generation and heat production together.

CHAPTER 9 - TRANSPORT

The rumble of diesel engines, on the other hand, will almost certainly still be heard in the post-apocalyptic world. A diesel engine is pretty versatile and can be run on vegetable oil processed into biodiesel by reacting the oil with the simplest alcohol, methanol, under alkaline conditions (by adding lye — either sodium or potassium hydroxide, as we saw in Chapter 5). Methanol, also called wood alcohol, can be produced by dry distillation of lumber (see here), but ethanol from fermentation will also do.

During the Second World War, nearly a million gasifier-powered vehicles kept essential civilian transportation running throughout Europe. Germany produced a version of the Volkswagen Beetle with all the wood gasification equipment installed smartly within the body, with a hole in the hood for loading more wood the only giveaway to its extraordinary power source; and the German army even deployed more than fifty Tiger tanks propelled by wood gasifiers in 1944.

Around 3 kilograms of wood (depending on its density and dryness) is equivalent to a liter of gasoline, and so the fuel consumption of producer gas cars is measured not in miles per gallon, but miles per kilogram — wartime gasifiers achieved around 1.5 miles per kilogram.

To be of practical use, the material properties of raw rubber need to be tweaked by vulcanization: it is melted with a sprinkling of sulfur and then poured into a mold to set. In the process the rubber’s coiled molecular chains become interlinked into a tough, resilient mesh by bridges of sulfur. This produces an almost indestructible substance, more elastic than native latex, which doesn’t become sticky when warm or brittle when cold.

The chemistry behind making synthetic rubber will be fiendishly tricky in the early stages of recovery, so once preexisting rubber supplies have deteriorated after the grace period, reestablishing long-distance trade will be one of your top priorities if you don’t live near a natural source.

The solution is to redesign the harness to shift the point through which the animal applies its force. The collar harness is a well-padded ring of metal or wood that fits snugly around the neck, with the draft-attachment points not behind the neck but lower on either side of the body, so as to evenly distribute the load around the horse’s chest and shoulders. This anatomically sound collar — an early application of ergonomic design — was developed in China in the fifth century AD, although it wasn’t widely adopted in Europe until the 1100s. It allows the horse to exert its full strength — the animal can deliver three times more tractive force than with the older, inappropriate harness—and horse-drawn plows thus became central to the revolution in medieval agriculture.

So if you peel back the skin of a brand-new sports car, something you might consider to represent the peak of modern technology, you’ll find a mishmash of components co-opted from mechanisms stretching far back through time: potter’s wheels, Roman sawmills, trip-hammers, wood lathes, and water clocks.

CHAPTER 10 - COMMUNICATION

In fact, the history of Western civilization itself was written in iron gall ink. Leonardo da Vinci wrote his notebooks with it. Bach composed his concertos and suites with it. Van Gogh and Rembrandt sketched with it. The Constitution of the United States of America was committed to posterity with it.

The screw press is a Roman technology dating back to the first century AD, used extensively for juicing grapes or extracting oil from olives. It also provides the ideal compact mechanism for applying a firm but even pressure onto two plates, squeezing the inked type onto the page. This key component of printing survives to this day in our collective name for the newspapers, and by extension the journalists who report for them: “the press.”

During the Second World War, both soldiers holed up at the front lines and those imprisoned in POW camps built their own makeshift radio receivers for music or news of the war effort. These ingenious constructions reveal the sheer variety of scavenged materials that can be jury-rigged to create a working radio. Aerial wires were slung over trees, or disguised as clotheslines, and sometimes even barbed wire fences were appropriated for the task. A good grounding was achieved by connecting to cold-water pipes in the POW barracks. Inductors were constructed by winding coils around cardboard toilet rolls, the scavenged bare wire insulated by candle wax, or in Japanese POW camps by applying a paste of palm oil and flour. Capacitors for the tuning circuit were improvised out of layers of tinfoil or cigarette-pack lining, alternating with newspaper sheets for insulation; the wide, flat device was then curled like a jelly roll to make a more compact component.

CHAPTER 11 - ADVANCED CHEMISTRY

Aluminum, too, can be teased from its rocky ore by electrolysis — it’s too reactive to be smelted using charcoal or coke. It is the most abundant metal in the Earth’s crust and a major constituent of one of the earliest materials to be employed by humanity — clay. Yet it was prohibitively expensive until the development of an effective method for melting and electrolyzing its ore in the late 1880s. Luckily, a recovering society will not immediately need to purify the metal afresh. Aluminum is so fantastically resistant to corrosion that it will remain uncorrupted for centuries after the apocalypse and can be recycled by melting at the relatively low temperature of 660°C, using the rudimentary furnace we encountered here

To create an explosion — a rapidly expanding pulse that assaults your eardrums, shatters a rock face, or pushes over a building — you need to suddenly create a bubble of very-high-pressure air in a small space. And the best way to accomplish that is with a frenzied flurry of chemical reactivity that converts solid substances into hot gases, which take up far more room and so quickly expand outward from the reaction point. A modern rifle, for example, contains roughly a sugar cube’s worth of powder in the charge behind the bullet, but when this is triggered it reacts with itself blindingly quickly to create a ball of gas about the size of a party balloon.

Ironically enough, the earliest explosive to be developed in history was first formulated by ninth-century Chinese alchemists seeking an elixir for immortality: black powder. Gunpowder consists of charcoal—the fuel or reductant—and saltpeter (now termed potassium nitrate), the oxidant, ground and mixed together. Sprinkling in some yellow elemental sulfur as a third ingredient changes the end products of the reaction and results in far more energy being left over for the concussive whump. An optimized gunpowder recipe is to mix equal parts of saltpeter and sulfur to six parts of charcoal fuel: a chemical cocktail taut with latent energy poised to burst out.

While gunpowder supports rapid combustion by intermingling fuel and oxidant powders snugly together, there is an even better way to ensure a more vigorous reaction and thus a more powerful explosion: combining the fuel and the oxidant into the same molecule. Reacting many organic molecules with a mixture of nitric and sulfuric acids (see Chapter 5) serves to oxidize them, tacking on nitrate groups to the fuel molecule. For example, oxidizing paper or cotton (which are both sheets of plant cellulose fibers) with nitric acid produces the heartily flammable nitrocellulose—flash paper or guncotton.

We often hear about the Industrial Revolution and the innovation of ingenious mechanical contraptions for alleviating the toil of humankind, thereby greatly accelerating the pace of progress and transforming eighteenth-century society. But the transition to an advanced civilization is as much about the invention of chemical processes for the large-scale synthesis of the necessary acids, alkalis, solvents, and other substances critical to the running of society as it is about machinery for automating spinning and weaving and building roaring steam engines.

In terms of the sheer number of people it directly affects every day, the most profound technological advance of the twentieth century was not the invention of flight, antibiotics, electronic computers, or nuclear power, but the means to synthesize a humble, foul-smelling chemical: ammonia.

Today, the Haber-Bosch process pumps out around a hundred million tons of synthetic ammonia every year, and fertilizer made from it sustains one-third of the world’s population — around 2.3 billion hungry mouths are fed by this chemical reaction. And since the raw materials in the food we eat become assimilated into our cells, about half of the protein in our bodies is made from nitrogen fixed artificially by the technological capability of our own species. In a way, we’re partially industrially manufactured.

CHAPTER 12 - TIME AND PLACE

A pendulum will swing with exactly the same beat even as friction and air drag gradually reduce the amplitude of its swing, and it is this incredible regularity that makes it such a useful component for a clock.

The morning of either equinox is easy to spot anywhere in the world, as the Sun rises due east (at right angles to the celestial pole you observed). It is this standard equinoctal hour (which can be captured from a sundial by an hourglass for comparison later) that mechanical clocks are set to count.

With the proliferation of mechanical clocks came a potential source of confusion, however — which of the two time systems do you mean: the uniform hour of machinery, or solar time, counting the number of hours since sunrise? Thus from the fourteenth century on it became necessary to specify a time as an hour “of the clock,” such as “three o’clock.”

Despite the slight trickiness in observing this star, it can serve as a natural time marker in the heavens. Barnard’s star, due to its nearness, has the fastest proper motion of any known star in the heavens. It tears across the sky at almost three one-thousandths of a degree every year.

Most usefully for navigation, the sextant can very precisely give you the elevation angle above the horizon of the Sun, or Polaris, or indeed any other star. The design of such a marvelously useful contraption is easy to replicate in retrospect, and as soon as your rebooting civilization has recovered the basic capabilities for shaping metal, grinding lenses, and silvering mirrors, you’ve nailed the prerequisite technologies for the sextant.

A post-apocalyptic civilization rebooting along a different pathway through the web of scientific discoveries and technologies may arrive at another solution to global navigation. They might find that building rudimentary radio sets (see Chapter 10) is an easier prospect than the fabulously intricate workings and compensatory mechanisms of a sufficiently accurate timepiece.

CHAPTER 13 - THE GREATEST INVENTION

But there is nothing inevitable about a sustained trajectory of scientific development or technological innovation, and even vibrant societies can lose the impetus to advance further.

the key trigger for the Industrial Revolution wasn’t knowledge. It was a particular socioeconomic environment.

Britain possessed not only abundant energy (coal), but an economy with expensive labor (high wages) coupled with cheap capital (the ability to borrow money to undertake large projects). Such circumstances encouraged the substitution of capital and energy for labor — replacing workers with mechanization such as automated spinners and looms. The economic situation in Britain had the potential to generate enormous profits for the first industrialists, and it was this that provided the incentive to put up large amounts of capital to invest in machinery.

The absolute root of science, then, is the careful design and construction of instruments for making measurements, as well as units to count these in.

Starting with the meter as the primary base unit, you can derive many others from it. Build a cube-shaped container with each interior side exactly 10 centimeters long (one-tenth of your meter). The internal volume of this box is 1,000 cm3, or one liter. Fill the container with ice-cold, distilled water, and the water will have a mass of exactly one kilogram. Use a set of well-constructed balance scales (hang a straight, stiff rod from its midpoint if you need to) and you can use this liter of water to create any fraction or multiple of this unit by moving the mass closer to or farther from the pivot. To bring time into the fold you can utilize the pendulum we encountered in the last chapter. The length of a pendulum that swings each way (i.e., a half-period) in exactly one second is 99.4 cm, and even if you used a meter-long pendulum it would still be accurate to within three milliseconds — a hundred times less than the blink of an eye. So, building from the meter alone you can reconstruct the metric units for volume (liter), mass (kilogram), and time (second).

In this way, science isn’t listing what you know: it’s about how you can come to know. It’s not a product but a process, a never-ending conversation rebounding back and forth between observation and theory, the most effective way of deciding which explanations are right and which are wrong. This is what makes science such a useful system for understanding the workings of the world—a powerful knowledge-generating machine. And this is why it is the scientific method itself that is the greatest invention of all.

The practice of canning food for preservation, for example, was developed long before the acceptance of germ theory and the discovery of spoilage by microorganisms.

Survivors of the Fall will appreciate the importance of scientific understanding and critical analysis, which will be crucial in maintaining relic technology as long as possible. But over the generations the post-apocalyptic society must protect itself against slipping into a rationality coma of superstition and magic, and must nurture an inquisitive, analytical, evidence-based mind-set for the rapid attainment of their own technological capability. This is the flame that the survivors must keep burning. It is by thinking rationally that we have been able to vastly improve our productivity in growing food, to master materials beyond sticks and flint, to harness power sources beyond our own muscles, and to build transportation to convey us much farther than our own feet ever could. It is science that built our modern world, and it is science that will be needed to rebuild again.

FINALE

have also provided below a list of a few of the most relevant sources for the general subject matter of each chapter of this book, as well as the references for specific points. Many of these books belong to the Appropriate Technology Library, as indicated by the ATL reference number in brackets after the title. The ATL consists of more than a thousand digitized volumes that have been selected for the practical information they provide on self-sufficiency and rudimentary techniques, and is available on DVD or CD-ROM from Village Earth at http://villageearth.org/appropriate-technology/. Full citation information is given in the bibliography, and also see The Knowledge website, the-knowledge.org, for links to all the cited literature, including free downloads where available.

In many respects, therefore, charcoal is a fuel superior to coal and is by no means confined to the history books. Brazil, for example, is blessed with abundant timber resources but few coal mines — a situation that is likely to be encountered more broadly in the post-apocalyptic world with regrowth of the forests — and is the largest charcoal producer in the world. Some of it is used in blast furnaces for creating pig iron that is exported to be made into steel for cars and kitchen appliances in the United States and elsewhere. Much of this charcoal is sourced from managed forestry, and so this offers opportunities for “green steel.”

WARNING: Never use aluminum pots or utensils for creating soap. Aluminum reacts vigorously with strong alkalis to release explosive hydrogen gas.

If you anticipate that you’ll want to run further impressions of the same body of text in the future, such as for subsequent print runs of an important treatise, you can save yourself the hassle of having to typeset thousands of individual letters all over again by saving the page configuration. The types themselves are too valuable to be left arranged in the frame, but you can take an impression of the text layout in plaster and then use this as a mold for casting a metal plate of the whole page. This is the original meaning of the word “stereotype.” The nickname for a stereotype plate is “cliché,” apparently after the sound made during the casting — and so to use a cliché is to rehash a block of commonly printed text.

How can you prove it is the Earth that moves around the Sun, and not vice versa (and thus that we are not in a privileged location in the center of the solar system)? All you need is a suitably accurate clock. Over a few nights you’ll notice that any given star rises almost exactly four minutes later each night. If the only motion involved were the Earth turning on its axis like a top, the stars would wheel into view at exactly the same moment every night. But in fact the Earth’s position shifts slightly, and so it takes a short while for its rotation to bring the same view as last night back into sight. Four minutes is 1/365 of 24 hours: the Earth has moved forward one day in its yearlong circuit of the sun.

About the only countries that haven’t fully adopted this system are the US and the UK, where outdated units persist with the use of miles on road signs and car speedometers and drinks served in restaurants and pubs by the pint. The historical reason was Napoleon excluding the English-speaking world when he convened a congress in 1798 to encourage international adoption of the new metric system — the British had just sunk the French fleet at the Battle of Aboukir and so were not invited to the party.

Similar, small-scale scenarios have occurred in recent history: with the fall of the Soviet Union in 1991, the small republic of Moldova experienced a crippling crash in its economy, forcing people to become self-sufficient, readopting museum-exhibit technology such as spinning wheels, hand looms, and butter churns.

Although only those for correcting farsightedness: the concave lenses for nearsightedness, which affects most people, disperse the light rays rather than focusing them. William Golding famously made this mistake in Lord of the Flies, with the nearsighted Piggy using his spectacles to start fires.